https://sammechanical.com/wp-content/uploads/2023/07/What-to-Ask-a-Potential-HVAC-Contractor.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-22 11:32:542026-01-08 16:47:58Questions to Ask HVAC Contractors Before Hiring Their Services

https://sammechanical.com/wp-content/uploads/2023/07/What-to-Ask-a-Potential-HVAC-Contractor.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-22 11:32:542026-01-08 16:47:58Questions to Ask HVAC Contractors Before Hiring Their ServicesHow to Extend the Life of Your Commercial Cooling Tower

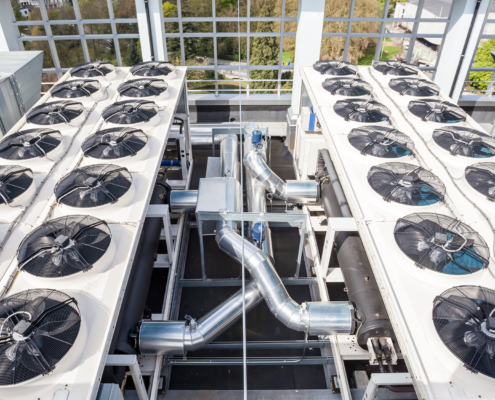

Commercial cooling towers are vital components in maintaining optimal temperatures and ensuring the efficiency of large-scale HVAC systems. However, without proper care and maintenance, these crucial systems can quickly become inefficient and worn down, leading to costly repairs and operational disruptions.

This article explores the essential steps you can take to extend the lifespan of your commercial cooling tower, ensuring it meets your business needs for as long as possible.

The Importance of Long-Lasting Cooling Towers

Maintaining a functional and efficient commercial cooling tower is crucial for ensuring optimal performance and reducing operational costs. Extending its lifespan through regular maintenance and upgrades enhances cooling efficiency but also improves overall system reliability. A well-maintained cooling system minimizes the risk of breakdowns, reduces energy consumption, and preserves water quality, contributing to sustainable operations and long-term cost savings for businesses.

The Role of Regular Inspections and Maintenance

Regular inspections and maintenance are crucial to ensuring the longevity of your commercial cooling tower. Let’s explore how they extend the lifespan and efficiency of your cooling systems.

Routine Inspections

Regular inspections are essential for catching potential issues early and preventing costly repairs. Schedule monthly inspections to check for leaks, signs of corrosion, and any unusual noises. It’s important to verify that all components, such as fans, motors, and pumps, operate smoothly. These proactive measures reduce maintenance costs and extend the lifespan of your cooling tower by ensuring optimal performance.

Preventive Maintenance

Implementing a robust preventive maintenance plan is key to maximizing the lifespan of your cooling tower. This includes regular cleaning of components, lubrication of moving parts, and timely replacement of worn-out parts. By proactively addressing wear and tear, you can minimize the risk of unexpected breakdowns and ensure consistent efficiency of your cooling system.

Keep your HVAC equipment in optimal shape this summer by taking a look at our maintenance checklist.

Extending Cooling Tower Longevity With Water Quality Management

Maintaining proper water quality is essential for the efficient operation of your cooling tower. From maintaining water chemistry to installing filtration systems, water quality plays a crucial role in the longevity of cooling systems.

Maintaining Water Chemistry

Maintaining proper water chemistry is critical for preventing issues like scale buildup, corrosion, and biological growth. Regularly testing and adjusting pH levels, hardness, and other chemical properties ensures the water remains balanced and contaminant-free. Using appropriate water treatment chemicals helps maintain optimal conditions within the cooling tower, prolonging its operational life.

Installing Filtration Systems

Effective filtration systems play a crucial role in enhancing the efficiency and longevity of your cooling tower. These systems remove debris and contaminants from the water, reducing the risk of clogs and improving overall system performance. Consider installing side-stream filtration systems that continuously clean a portion of the circulating water to further enhance the effectiveness of your water treatment efforts.

Optimizing Cooling Tower Operations

Optimizing cooling tower operations contributes to energy efficiency and extends the lifespan of equipment. But how can you enhance the efficiency of your cooling systems?

Adjust Fan Speed

Utilizing variable speed drives (VSDs) to adjust fan speeds based on cooling demand optimizes energy usage and reduces wear on fan motors. This adjustment not only lowers operational costs but also extends the lifespan of your cooling system equipment by minimizing stress on mechanical components.

Monitor Temperature and Flow Rates

Monitoring water temperature and flow rates using sensors allows for real-time adjustments to maintain optimal operating conditions. By ensuring that the cooling tower operates within manufacturer-recommended parameters, you can identify potential issues early and take proactive measures to prevent system inefficiencies and premature wear.

Why Keeping Your Commercial Cooling Tower Clean Is Essential

Regular cleaning is essential for maintaining the efficiency and performance of your cooling tower and maximizing its lifespan.

Regular Cleaning

Regular cleaning of all cooling tower components, especially fill media and basin surfaces, prevents the buildup of dirt, algae, and other contaminants. This maintenance task is crucial for maintaining efficient heat transfer and preventing blockages that can impair system performance over time. Use safe and effective cleaning agents to preserve the integrity of cooling system materials while ensuring optimal cleanliness.

Prevent Biological Growth

Biological growth, such as algae and bacteria, can compromise cooling tower efficiency and lead to corrosion and foul odors. Incorporating biocides and algaecides into your water treatment regimen effectively controls microbial growth. This proactive approach maintains clean tower surfaces and ensures consistent performance, extending the lifespan of your cooling tower system.

The Need for Regular Component Upgrades

Upgrading components enhances the performance and efficiency of your cooling system. Let’s explore some of the ways you can upgrade your cooling systems to ensure they last as long as possible.

Replace Worn-Out Parts

Timely replacement of worn-out components such as fans, motors, nozzles, and fill media is essential for maintaining peak performance and reliability. High-quality replacements help improve efficiency and minimize the risk of unexpected failures, extending the operational life of your cooling tower.

Upgrade to Energy-Efficient Components

Upgrading to energy-efficient fans, motors, and other components reduces energy consumption and operating costs while enhancing cooling tower efficiency. These upgrades offer long-term savings and sustainability benefits, making them a worthwhile investment for extending the lifespan of your cooling tower system.

How Staff Training Improves Equipment Longevity

Properly trained staff ensure the effective operation and maintenance of your cooling tower system. Here are some ways to give your employees the best chance at keeping cooling systems in peak condition.

Proper Training

Comprehensive training for maintenance staff on cooling system operations and maintenance practices ensures they can effectively perform inspections, routine maintenance, and repairs. Well-trained personnel are essential for detecting and addressing issues promptly, adhering to safety protocols, and maximizing the longevity of your cooling tower system.

Stay Updated

Keeping your maintenance team informed about the latest industry best practices and technological advancements through regular training sessions and workshops is crucial. This ongoing education ensures your staff remains knowledgeable and proficient in cooling tower maintenance, enabling them to implement efficient practices that extend the lifespan of your cooling tower and optimize operational performance.

While training your staff is important, it’s also wise to entrust the longevity of your cooling systems to experienced professionals, like those at SAM Mechanical Services.

Get the Most Out of Your Commercial Cooling Tower With SAM Mechanical Services

SAM Mechanical Services is committed to helping you maximize the performance and longevity of your commercial cooling tower. With regular maintenance and dedicated support, we ensure your cooling tower operates efficiently and reliably, leading to increased efficiency and significant cost savings. SAM Mechanical provides the expert care your cooling tower needs for optimal performance and extended lifespan.

Contact our team today to maximize your cooling tower lifespan.

Share This Post

More Like This

https://sammechanical.com/wp-content/uploads/2023/07/What-to-Ask-a-Potential-HVAC-Contractor.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-22 11:32:542026-01-08 16:47:58Questions to Ask HVAC Contractors Before Hiring Their Services

https://sammechanical.com/wp-content/uploads/2023/07/What-to-Ask-a-Potential-HVAC-Contractor.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-22 11:32:542026-01-08 16:47:58Questions to Ask HVAC Contractors Before Hiring Their Services https://sammechanical.com/wp-content/uploads/2024/07/How-to-Choose-the-Right-Coolant-for-Your-Chiller.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-17 15:02:272025-01-07 15:57:34How to Choose the Right Coolant for Your Chiller

https://sammechanical.com/wp-content/uploads/2024/07/How-to-Choose-the-Right-Coolant-for-Your-Chiller.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-17 15:02:272025-01-07 15:57:34How to Choose the Right Coolant for Your Chiller https://sammechanical.com/wp-content/uploads/2024/07/Choosing-the-Right-Size-for-Your-Commercial-Chiller-Installation.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-15 16:41:152025-01-21 16:00:00Choosing the Right Size for Your Commercial Chiller Installation

https://sammechanical.com/wp-content/uploads/2024/07/Choosing-the-Right-Size-for-Your-Commercial-Chiller-Installation.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-07-15 16:41:152025-01-21 16:00:00Choosing the Right Size for Your Commercial Chiller Installation https://sammechanical.com/wp-content/uploads/2024/05/HVAC-Air-Chillers-on-Rooftop.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-05-21 12:17:032025-01-07 15:57:36Chiller Retrofits: Enhancing Performance and Efficiency in Older Systems

https://sammechanical.com/wp-content/uploads/2024/05/HVAC-Air-Chillers-on-Rooftop.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-05-21 12:17:032025-01-07 15:57:36Chiller Retrofits: Enhancing Performance and Efficiency in Older Systems https://sammechanical.com/wp-content/uploads/2024/05/Side-view-of-an-industrial-chiller-or-air-conditioner-on-rooftop.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-05-21 12:07:442025-01-07 15:57:36The Importance of Regular Chiller Maintenance

https://sammechanical.com/wp-content/uploads/2024/05/Side-view-of-an-industrial-chiller-or-air-conditioner-on-rooftop.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2024-05-21 12:07:442025-01-07 15:57:36The Importance of Regular Chiller Maintenance https://sammechanical.com/wp-content/uploads/2023/05/chiller-on-the-roof-in-the-building_.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2023-05-18 09:00:572025-01-07 15:57:47Optimize Commercial Chiller Efficiency in 2023

https://sammechanical.com/wp-content/uploads/2023/05/chiller-on-the-roof-in-the-building_.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2024/01/sam-logo-crete-300x154.png

AbstraktMarketing2023-05-18 09:00:572025-01-07 15:57:47Optimize Commercial Chiller Efficiency in 2023About

For over three decades SAM Mechanical has provided New Hampshire with the highest quality HVAC, plumbing, and mechanical services.